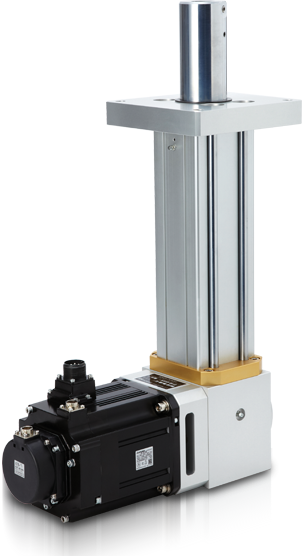

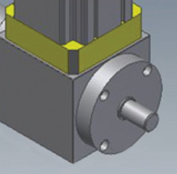

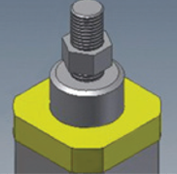

Power Cylinder

Specification

| Item | Power Cylinder | Feature | |||

|---|---|---|---|---|---|

| Lubrication | Grease | · Precision machining of each part · Use of the best material |

|||

| Material | Aluminium · STKM13C | ||||

| Gear | Spiral Bevel Gear | Worm Gear | Sper Gear | Helical Gear | · Smooth drive with noise and vibration resistant design |

| Ratio | 1:1 ~ 4:1 | 10:1 ~ 30:1 | 1: 1 ~ 5:1 | ||

| Efficiency(%) | 94 ~ 97% | 50 ~ 30% | 94 ~ 97% | ||

| Max. Input Speed(rpm) | 1,500rpm | ||||

| Protection Class | IP65 | · Avoid particle generation | |||

| Life Cycle(h) | > 10,000 | · Longest time durability implementation · Designed to prevent damage due to internal shock |

|||

| Orientation | Any | ||||

| Installation Direction | Horizontal, vertical, oblique, etc. No installation angle limit | ||||

| Ambient Temperature (℃) | -20 ~ 50℃ | ||||

| Ambient Humidity (%) | Less than 80% | ||||

| Altitude | Altitude less than 1,000m | ||||

| Terms of Use | No corrosive or explosive gas | ||||

Model Number

Size, Gear Type & Ratio, Serew Type,

Outdia, Lead, Bellows Yes or no, Stroke System

Outdia, Lead, Bellows Yes or no, Stroke System

MSR45 B2 - BL 3210 - B 500ST

| Power Cylinder Specification |

|---|

| Gear Type & Reduction Ratio |

|---|

| B : Bevel Gear Ratio (B, B2, B3) W : Worm Gear Ratio (W15, W20, W30) H : Helical Gear(H3) S : Spur Gear(S2.5) |

| Stroke |

|---|

| Bellows Yes, No |

|---|

| Outdia, Lead |

|---|

| Screw Type |

|---|

| BL : Ball Screw TL : TM Screw |

Use Guide

Most importantly,

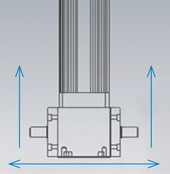

If the cylinder is not leveled,

If the cylinder is not leveled,

- Most importantly,

if the cylinder is not leveled,

it will cause noise and vibration

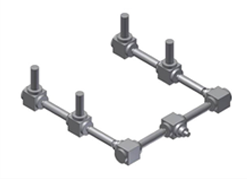

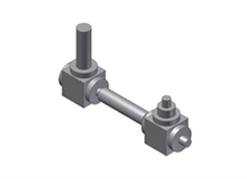

- When combining two or more rotating and lifting and lowering machines, they must be arranged in such a way that the center of rotation and elevation center line are aligned exactly so that the twisting, thermal expansion and bearing load of the motion shaft can be properly distributed

- ROD eccentricity can occur

when the cylinder is

assembled forcibly on

the frame to be mounted,

which has a serious

effect on the life

of the cylinder.

- You must be taken

to prevent twisting by

assembly bolts when

assembling the upper

and lower part

- Keep the Level of each cylinder

the same by using the screws

located at the end of the ROD.

If Level is not maintained,

divergence to one side

and overload of motor may occur.

Applications

Design and installation conditions may vary,

so please contact us if you have any questions

so please contact us if you have any questions

| Model | Main | Sub |

|---|---|---|

| MSR45 | S45 | S45 |

| MSR75 | S90 | S75 |

| MSR80, MSR10 | S90 | S75 |

| MSR110, MSR20W | S120 | S110 |